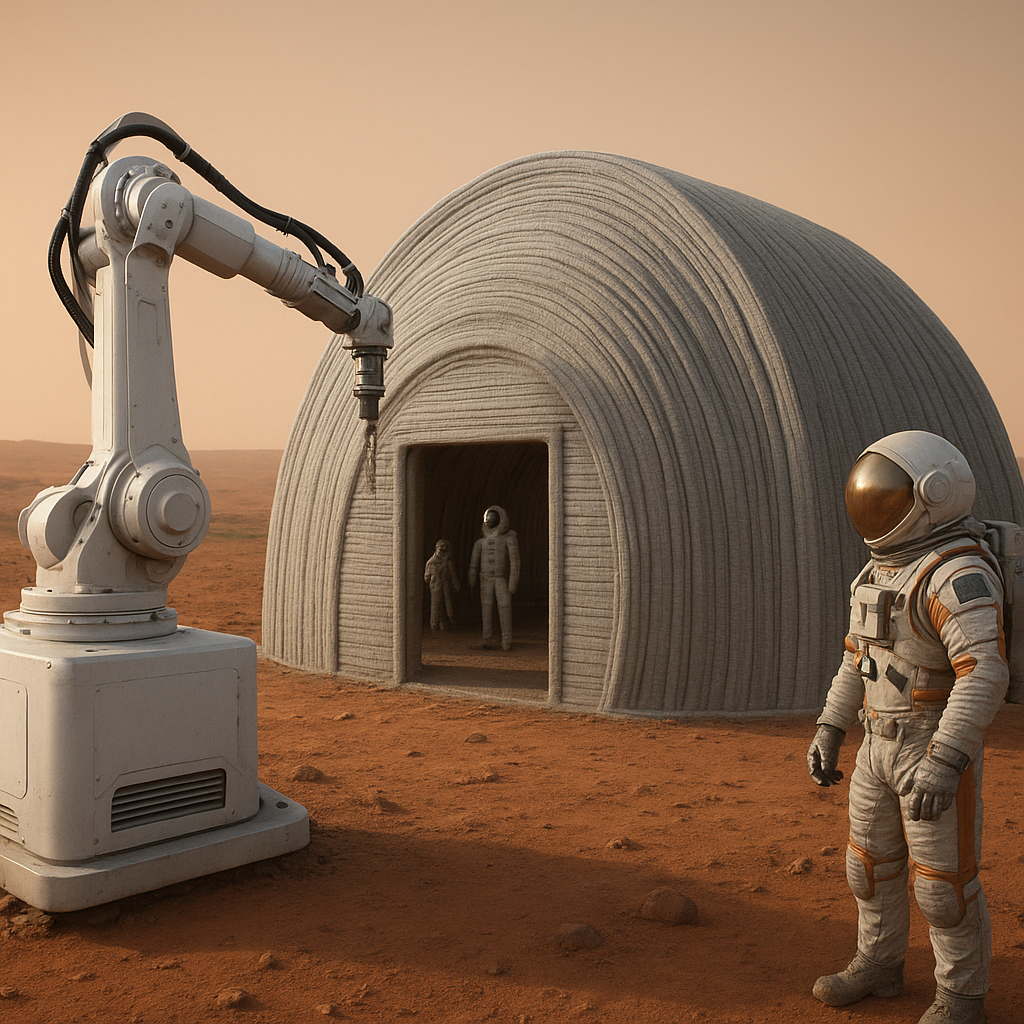

The convergence of 3D printing technology and space agriculture marks a pivotal advancement in humanity’s quest to establish permanent outposts beyond Earth. By leveraging additive manufacturing, researchers and engineers can design and construct robust, adaptive greenhouse structures directly in orbit or on planetary surfaces. This synergy promises to enhance sustainability, reduce launch costs, and foster self‐sufficiency for future astronauts and colonists.

Designing 3D Printed Greenhouses for Space Missions

Traditional greenhouse construction relies heavily on materials shipped from Earth, increasing payload weight and mission complexity. Additive manufacturing offers a transformative alternative: on‐site production of structural components using locally available or lightweight materials.

Material Selection and Biomaterials

- Regolith‐based composites—By mixing lunar or Martian soil with polymer binders, engineers can produce building blocks that withstand radiation and extreme temperatures.

- Biopolymers—Derived from plant biomass or microbial fermentation, these sustainable materials reduce reliance on synthetic resins and can degrade safely at end of life.

- Metals and alloys—Using selective laser melting, thin‐wall titanium or aluminum lattices provide high resilience against micrometeoroid impacts.

Structural Innovation and Modularity

Greenhouse designs incorporate modular panels that snap together, enabling rapid assembly and reconfiguration. Additive techniques allow for:

- Customized insulation patterns to maintain optimal temperature.

- Internal support lattices that minimize material usage while maximizing strength.

- Embedded sensor conduits for real‐time monitoring of pressure, humidity, and resource efficiency.

Advanced 3D printers aboard spacecraft or surface habitats can switch between feedstocks—such as polymer filaments, metal powders, and regolith composites—through automated tool changes, ensuring continuous production even in remote locations.

Cultivating Crops in Microgravity Environments

Microgravity and reduced gravity present unique challenges to plant growth, from altered water distribution to root orientation issues. To overcome these constraints, horticultural systems must integrate automation and adaptable infrastructure within the 3D printed greenhouse modules.

Hydroponics, Aeroponics, and Beyond

- Hydroponic channels printed directly into the floor panels ensure precise nutrient delivery and recirculation.

- Aeroponic misting systems, embedded within wall segments, allow roots to access oxygen‐rich environments, promoting faster growth cycles.

- A hybrid system combining both approaches can optimize water use and reduce pump power consumption.

Automation and Robotics

Robotic arms, printed with high‐precision polymer joints, handle seeding, pruning, and harvesting tasks. Integrated with AI algorithms, these robots adapt to plant health data, adjusting lighting, nutrient concentrations, and water flow. Key aspects include:

- AI‐driven monitoring—Continuous analysis of leaf color, turgor, and root health using computer vision.

- Self‐reconfiguring grow beds that adjust their orientation to optimize light exposure in low‐gravity conditions.

- Drone‐like inspection units that navigate greenhouse corridors to perform maintenance and deliver supplies.

Resource Management and Sustainability in Space Agriculture

Efficient recycling of resources is critical to long‐duration missions. 3D printed greenhouses can integrate closed‐loop systems that minimize waste and harness the full potential of biological processes.

Water and Nutrient Recycling

- Condensate collection channels, printed with hydrophilic coatings, capture transpired moisture effectively.

- Biofilm filters treat graywater from crew activities, converting it into nutrient solutions for the plants.

- Electrodialysis membranes, fabricated as thin layers in wall panels, separate ions and replenish mineral balances without bulk chemical shipments.

Carbon Dioxide Conversion and Oxygen Production

- Microalgae photobioreactors, integrated into transparent roof sections, convert CO₂ into O₂ while producing edible biomass.

- Chloroplast‐enhanced plant varieties grown in specialized pods can accelerate photosynthesis under LED lighting.

Waste Valorization and Bioregenerative Loops

Organic waste from kitchen scraps and plant residues is processed through 3D printed compost reactors that employ thermophilic microbes to generate fertilizer. The resulting humus enriches regolith substrates, boosting plant productivity. This bioregenerative approach ensures minimal external inputs and contributes to long‐term mission resilience.

Advanced Mission Architectures and Future Applications

As missions extend to Mars, the Moon, and beyond, 3D printed greenhouses will serve as cornerstones of extraterrestrial settlement. Engineers are exploring adaptive designs that respond to varying gravity fields, radiation levels, and mission objectives.

Inflatable‐Reinforced Hybrid Structures

- Deployable inflatable shells provide initial pressurization; subsequent 3D printing layers reinforce the habitat.

- Composite coatings embed radiation‐absorbing minerals, shielding crops and crew from cosmic rays.

Distributed Manufacturing Networks

In a fully operational base, multiple printers located at strategic nodes produce spare parts, sensor modules, and greenhouse extensions on demand. A digital inventory of design libraries allows for rapid scaling and customization to local conditions. Key factors include:

- Standardized interface ports for linking modular greenhouse segments and power systems.

- Open‐source design repositories that evolve with ongoing research and crew feedback.

- Real‐time telemetry between orbital facilities and surface habitats, enabling remote diagnostics and updates.

Terraforming Support and In Situ Resource Utilization

Beyond supplying food and air, 3D printed bioreactors and greenhouses may play roles in long‐term terraforming efforts. Engineered microorganisms cultivated within printed biocontainers could extract water ice and produce soil amendments. Over centuries, such systems could transform barren landscapes into semi‐arable fields, gradually preparing them for higher plant species and human habitation.

By intertwining innovation in additive manufacturing with cutting‐edge agricultural science, humanity moves closer to realizing true off‐world colonization. The prospect of bioregenerative life support, powered by robotics and microgravity agritech, heralds a new era of exploration—one where every meal grown under an alien sky demonstrates the ingenuity and sustainability of Earth’s finest minds.